#Slider start page = 7

Gas technology

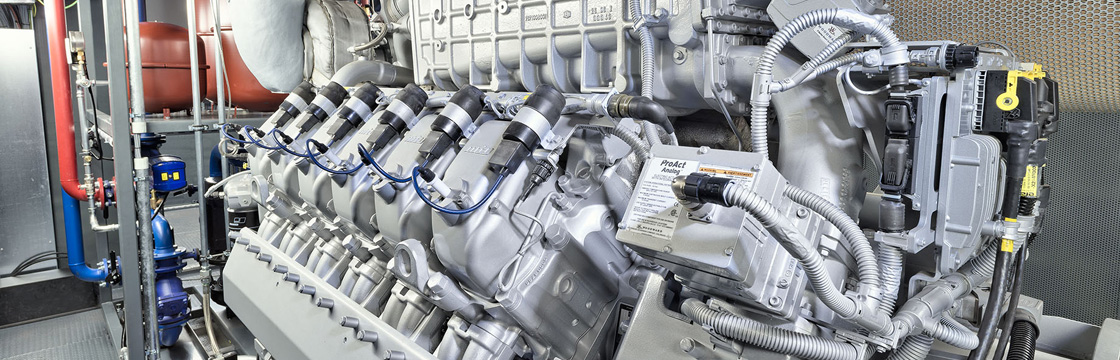

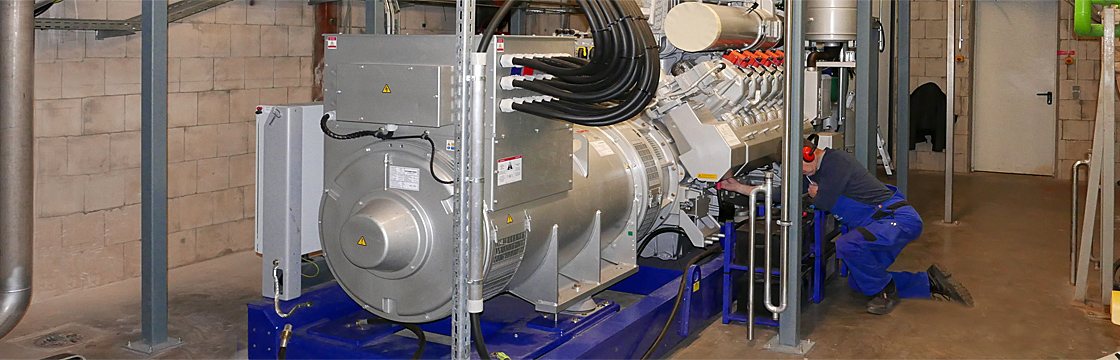

To ensure a safe and long-term plant operation, a gas processing system, which is adjusted to the respectively selected gas engine manufacturer, is of great importance.

In this case GTP offers customized solutions for the three well-known engine manufacturers:

Together with the client the exact implementation of the gas processing will be determined project-specifically. In this process the individual gas quality of the plant will be taken into account. Special requests can also be taken into consideration.

-

Gas drying

Untreated gas is 100% water-saturated. For a continuous motor operation, the relative humidity has to be reduced. This is ensured by:

- Cooling of the gas

- Condensate removal

- Gas reheating

-

Activated carbon for purification

Chemical gas purification by activated carbon to remove harmful substances, typical for the gas engine:

- Hydrogen sulfides

- Siloxanes

- Ammonia

-

Biological purification

The desulfurization plant is 100% biological and the operating costs lie 80-90% below the cost for chemical processes. Liquid waste water is the only product out of this process and can be used as fertilizer.

-

Gas flares

The flare has the role to burn the excess biogas in an environmentally sound manner. It usually starts running in case of engine troubles or burns off excess gas. It also prevents methane emissions into the environment.

-

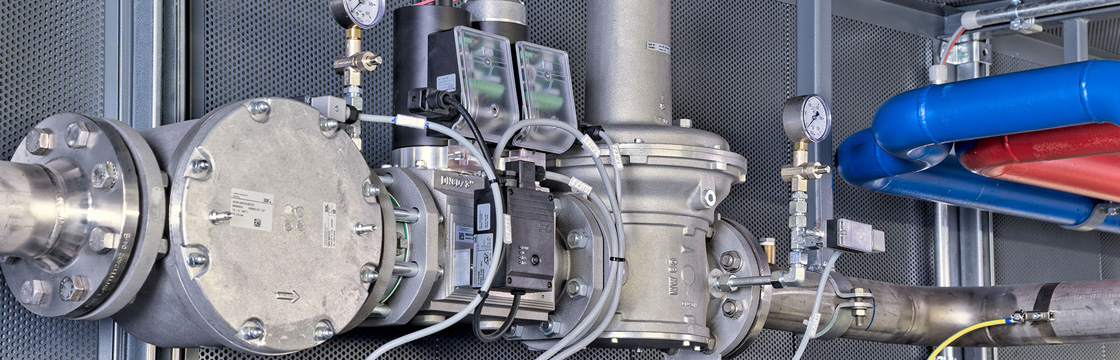

Booster stations

Booster stations have the task to increase the pressure of the fuel gas to operate a gas engine. In the case of biogas plants, the pressure inside the process is too low, to be used directly in gas engines.